The Food industry is complicated. The supply-chain from growing through harvesting, formulating, processing, labeling, and manufacturing impacts everyone.

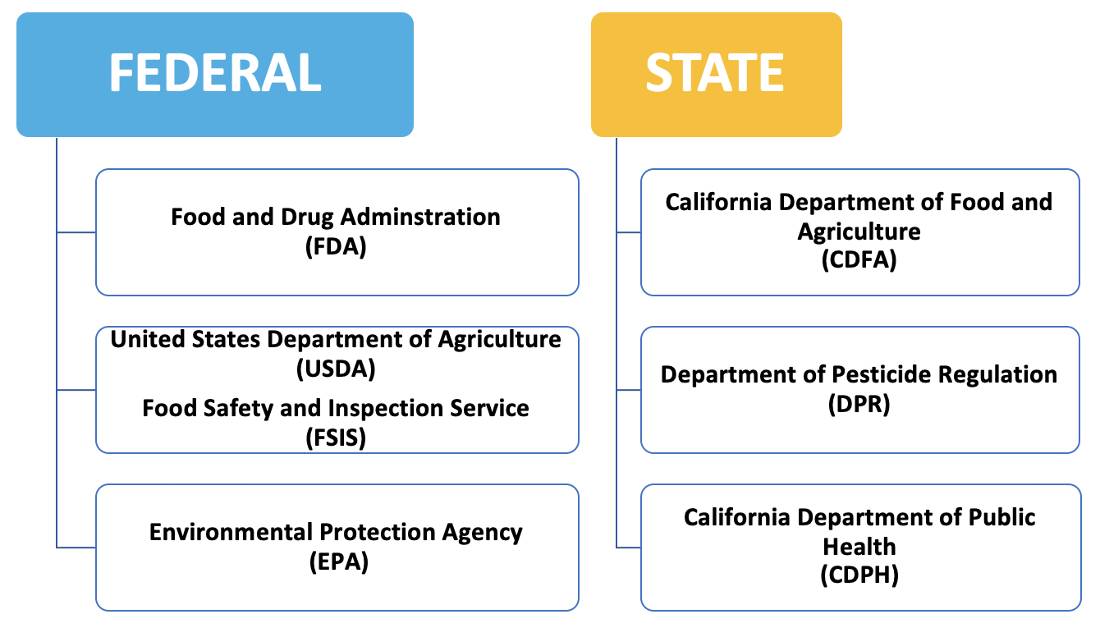

Example: Using the State of CA

Farms

Produce Safety Rule

Agricultural water

- Water quality - includes water used for cleaning of food contact surfaces or direct produce contact (including ice) during or after harvest, and for hand washing.

- Water testing - the general approach to testing untreated water used for certain purposes.

Biological soil amendments

- Raw manure - the applications of manure as a soil amendment and harvesting to minimize the risk of contamination.

- Stabilized compost - Microbial standards that set limits on detectable amounts of bacteria.

Sprouts

Domesticated and wild animals

The feasibility of compliance for farms that rely on grazing animals (such as livestock) or working animals for various purposes. It establishes the same standards for these animals as it does for intrusion by wild animals.

Worker training, health and hygiene

Taking measures to prevent contamination of produce and food-contact surfaces by ill or infected persons.

Equipment, tools, and buildings

Standards related to equipment, tools and buildings to prevent these sources, and inadequate sanitation, from contaminating produce.

Exemptions – who does the rule apply to? Training: Produce Safety Alliance

Transportation Companies

Sanitary Transportation

Wash, Pack, Process, Manufacture, Store, and Some Producers of Food Supplies

Good Manufacturing Practices and Preventative Controls Rule

Food Safety Plan

- Process controls - procedures that ensure the control parameters are met.

- Food Allergen controls - written procedures the facility must have and implement to control allergen/s.

Sanitation controls - procedures, practices, and processes to ensure that the facility is maintained in a sanitary condition to minimize or prevent hazards. Oversight and management – a facility must make sure that the controls are being met.

- Monitoring - assurance that preventive controls are consistently performed.

- Corrections – identify and correct problems

- Corrective actions – documentation of corrected problems

- Verification – scientific validation

All Segments of the Food Chain

Intentional Adulteration

Food Defense Plan

Vulnerability assessment - Identification of vulnerabilities such as ability to contaminate the product or have physical access to the product. Mitigation strategies - How identified vulnerabilities will be eliminated or controlled. Mitigation strategy management components - Defines the mitigation strategy. Monitoring - Creating and implementing procedures, including:

- Corrective actions and

- Verification tasks

All Segments of the Food Chain

Food Traceability

Under FDA’s “New Era of Smarter Food Safety” initiative, the food traceability requirements are focusing on specific risk-based food types, defining a critical food event that must be tracked and key data element and how these records must be provided to the FDA in the event of a food safety outbreak.

Food Traceability List – A risk based ranking model for upcoming increased food traceability requirements. Critical Tracking Events – defines the steps in the food chain process that requires specific actions and tasks occur for:

- Growing – additional requirements for sprouts

- Receiving – defining the “first receivers” responsibilities

- Creating – creating food versus transforming food definitions and impact of foods on the Food Traceability List.

Importers of Food, Ingredients and Supplies

Foreign Supplier Verification Program (FSVP)

Importers are required to conduct risk-based activities to verify the food they are importing has been grown, manufactured, processed, packaged etc. to standards like the US.

Scope – defines who is responsible party or the importer is, under the rule. Hazard Analysis – the importer is required to identify the risks associated with the food and ensure proper supplier controls are in place to prevent, eliminate or control the hazard, throughout the food chain. Evaluation of Supplier Performance - The importer must evaluate:

- The hazard analysis must be evaluated by a Qualified Individual (QI) as defined by the FDA.

- Procedures, processes and practices for safety of food

- Food safety history of the supplier

- Storage and transportation practices

Supplier Verification – Verification activities may vary depending upon the risks previously identified but may include:

- Onsite Audits of the supplier’s facility

- Sampling and testing

- A review of the supplier’s relevant food safety records

Corrective Actions – the obligations of the importer in the event of an adverse food safety issue. Exemptions and Modified Standards – some food categories and company size and functions can result in modified or exempt requirements.